The Principle of Laser Welding for Plastics

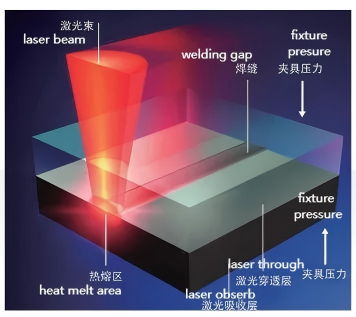

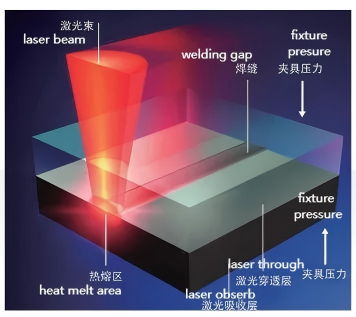

Laser welding of plastics requires that the upper and lower layers of materials to be welded exhibit good transmittance and good absorption of a specific wavelength of laser light, respectively. Based on this, laser welding of plastics is also called laser transmission welding. The principle of laser welding is shown in the figure.

During welding, the laser penetrates the upper material and is absorbed by the lower material at the interface between the upper and lower layers, generating heat. This heat transfers between the two layers, melting the interface. Under the pressure of the welding fixture and thermal expansion, the plastic macromolecules in the molten state diffuse and entangle with each other, producing van der Waals forces to achieve welding.

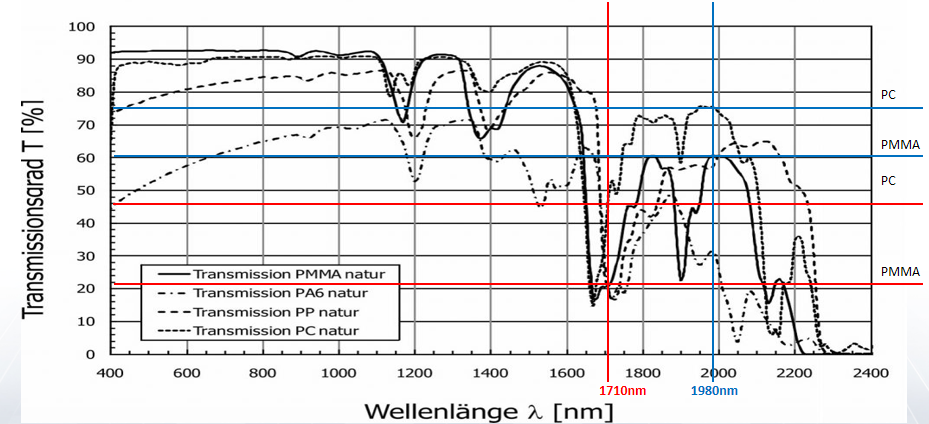

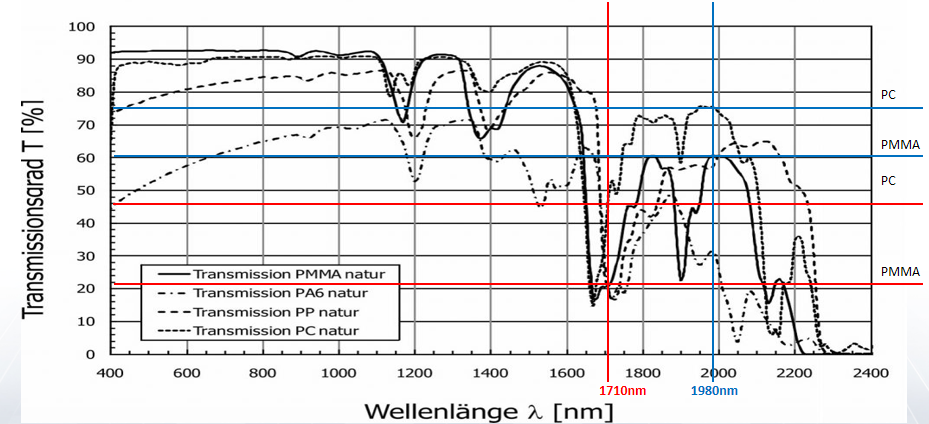

Absorption spectra of common plastics Transmittance of laser light of different wavelengths through transparent PMMA and PC plastics

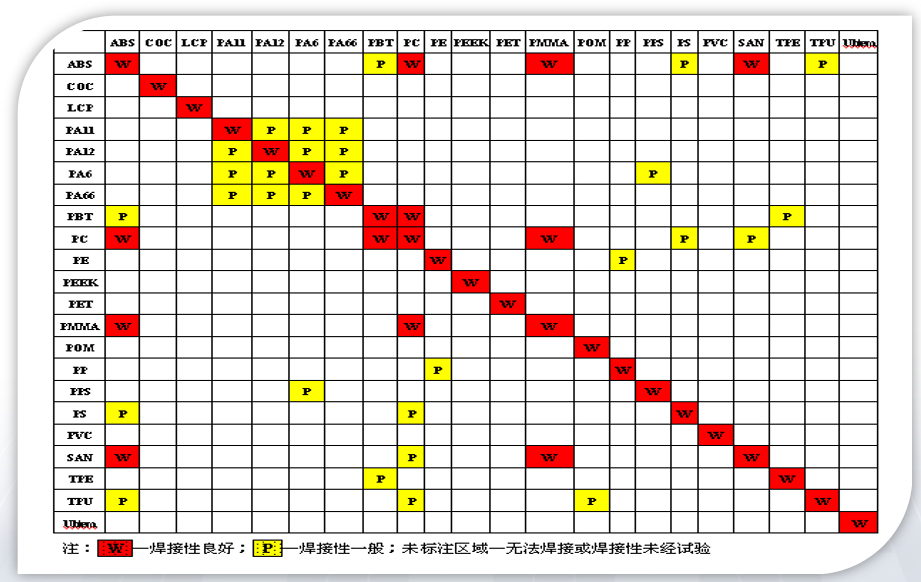

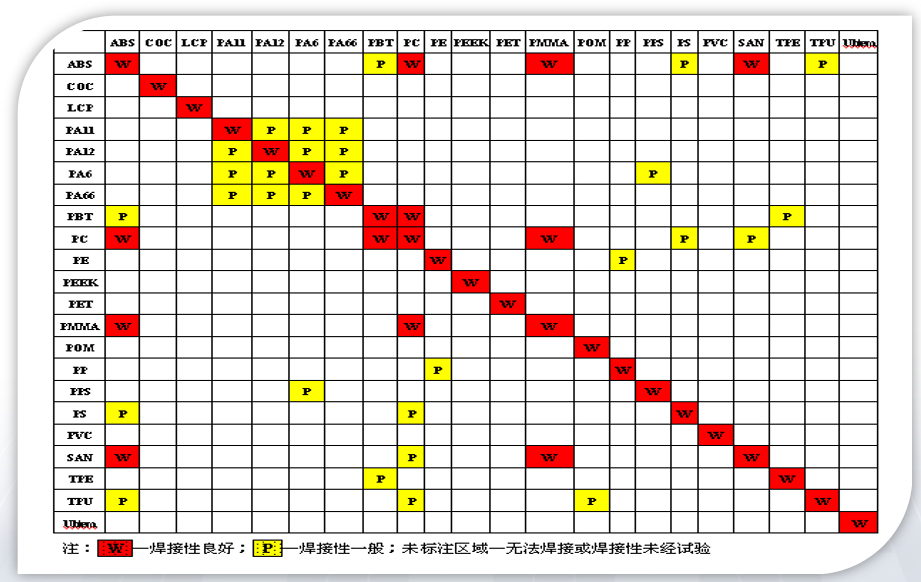

Plastic Laser Welding Material Range (W means well, P means poor )

The left graph shows the transmittance of several transparent plastic materials across different wavelengths. It can be observed that the transmittance of these plastics is relatively high for wavelengths below 1200 nm, while the absorption rate increases significantly for wavelengths above 1200 nm. Generally speaking, optimal laser welding results are achieved when the laser transmittance of the upper material exceeds 50% and that of the lower material is less than 20%. The graph on the right illustrates the weldability of commonly used plastic materials.

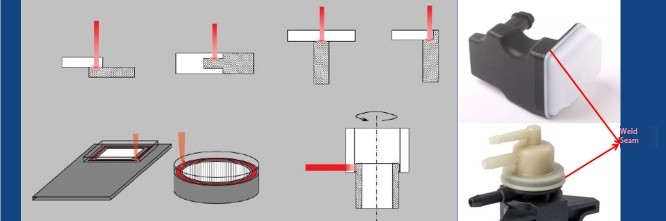

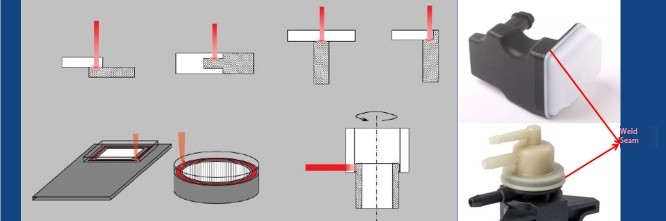

Since the plastic welding process requires the application of pressure, corresponding structural requirements are imposed on the plastic parts to be welded. As shown in the figure below, plastic parts are typically designed with an overlap joint structure for welding. For tubular parts, laser welding can be achieved through an interference fit.

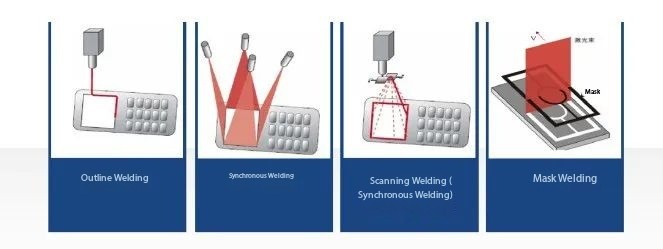

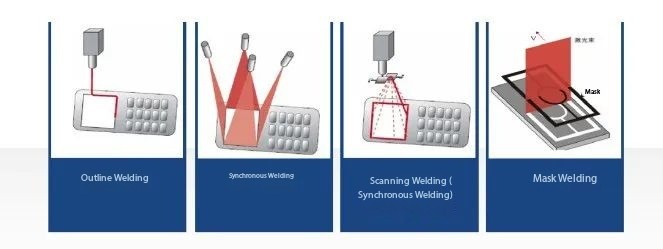

Types of Plastic Laser Welding Methods

Plastic laser welding methods are generally classified into four categories:

(1) Contour Welding: The laser moves along the contour of the plastic welding layer, melting it to gradually bond the plastics. It is mainly used for welding parts with regular shapes and requirements for welding speed.

(2) Simultaneous Welding: A laser emitter equipped with multiple laser ports is used, and the direction and shape of the laser beam are adjusted via optical components. Guided by a program, the laser beam welds along the contour of the welding layer, enabling the entire contour to melt and bond simultaneously. It is primarily suitable for welding parts with large contact areas and high requirements for welding consistency.

(3) Scanning Welding: Also known as quasi-simultaneous welding, it integrates the above two welding technologies. Optical devices generate a high-speed laser beam that moves along the area to be welded, causing the entire welding joint to gradually heat up and fuse. This method has high requirements for laser emission equipment.

(4) Mask Welding: A prefabricated mask is used to block the laser beam in ineffective areas, exposing only the precise welding zone. Welding is achieved by melting only the target area. This welding technology offers high precision and is currently widely applied due to its strong equipment versatility, simple mask fabrication, low cost, and ability to achieve high-precision welding down to 10μm.