Time:2024-08-24

pulsed laser with high beam quality and high-power laser output that uses a low-power laser with high beam quality as the seed light source and achieves high beam quality and high-power laser output through a single-stage or multi-stage fiber amplification system.

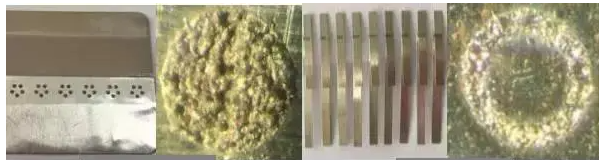

mopa product features include adjustable pulse width, frequency adjustable, single pulse energy, and so on. Widely used in precision marking, black marking, colorful marking, deep engraving, precision welding, precision cutting, and other applications.

These lasers excel in a variety of applications and are particularly suitable for:

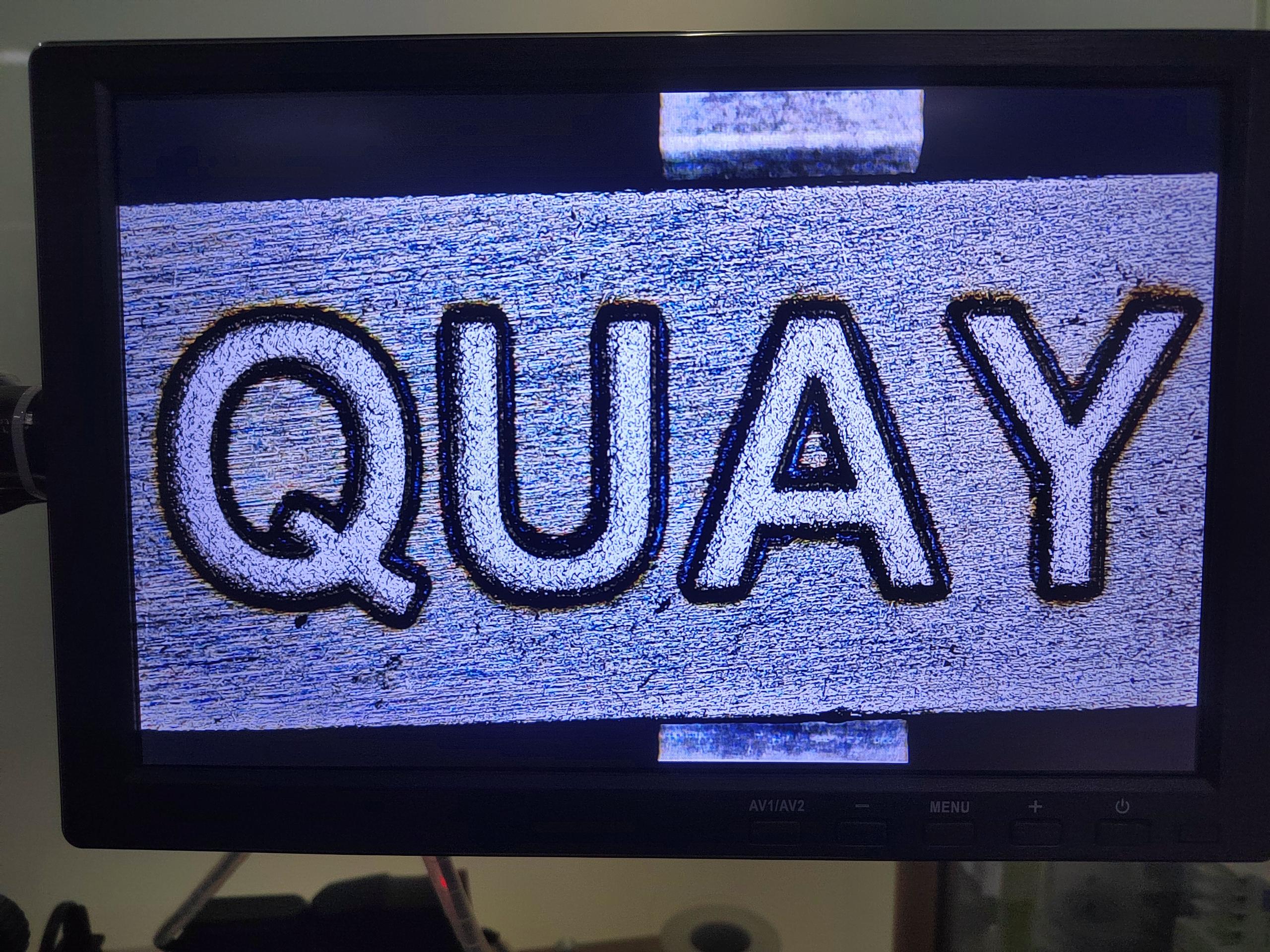

Precision marking: Mopa series lasers provide high-quality beams that can be used to achieve high-precision marking on various materials, such as trademarks, dates, serial numbers, etc.

Black marking: It is suitable for black marking on materials such as anodized aluminum to identify products in a clear and durable way.

Color Marking: The frequency tunability of these lasers enables color marking for creating colorful marks and logos.

Deep engraving: Mopa series lasers can achieve deep engraving, used to create fine patterns and structures on metals and other materials.

Precision welding and cutting: These lasers have high energy output and are suitable for high-precision welding and cutting applications such as electronic component manufacturing and materials processing.

Gear Laser Cutting

Mopa nanosecond battery busbar welding

100W mopa lasers are high-performance, multi-functional pulse laser systems suitable for various industrial and manufacturing applications, providing users with excellent control performance and high-quality laser output.

What is Mopa laser source

MOPA laser, the full name of Master Oscillator Power-Amplifier, is a laser structure composed of a cascade of laser oscillator and amplifier.

In the industrial world, MOPA laser refers specifically to a more "intelligent" nanosecond pulse fiber laser composed of an electrical pulse-driven semiconductor laser seed source and a fiber amplifier.

The following is a detailed introduction to MOPA lasers:

1. Basic components of MOPA laser

MOPA laser consists of two parts: Master Oscillator and Power Amplifier.

The main oscillator is responsible for generating high-quality seed light, and the power amplifier amplifies the seed light to achieve high-power output.

2.Characteristics of MOPA laser

1. **Frequency Adjustability**: The laser pulse frequency generated by the main oscillator can be adjusted by adjusting the main oscillator.

2. **Power amplification**: The power amplifier can significantly enhance the power output of the laser to meet the needs of various high-power applications.

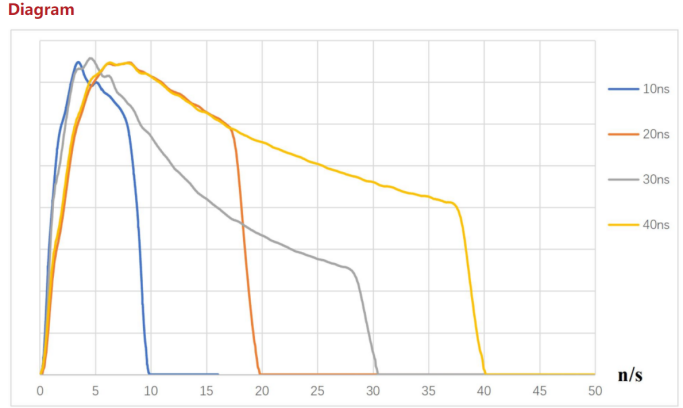

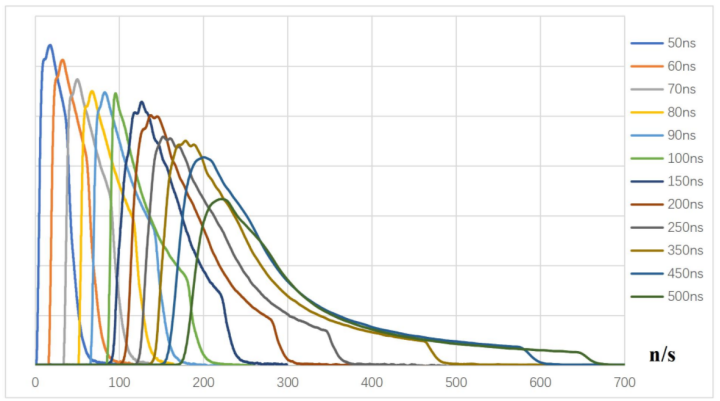

3. **Adjustable pulse width**: By controlling the pulse width of the main oscillator, the output pulse width can be accurately adjusted. This feature enables MOPA lasers to more precisely control the laser energy distribution during processing.

4. **High flexibility**: MOPA lasers have high flexibility and are suitable for various application scenarios that require precise control of laser parameters.

Adjustable Pulse Width: MOPA lasers allow for variable pulse width (ranging from nanoseconds to microseconds), which provides flexibility in marking different materials. This adaptability helps to control heat input and achieve the desired marking effect.

High Precision: The ability to fine-tune laser parameters allows for high-precision marking, making MOPA lasers ideal for applications that require detailed and intricate patterns.

Versatility: MOPA lasers are suitable for a wide range of materials, including metals (such as stainless steel, aluminum, and titanium), plastics (like ABS, PVC, PET), and other sensitive materials.

High-Quality Marking: MOPA lasers can produce high-contrast, sharp, and clear markings on various surfaces, making them suitable for applications requiring permanent marks, such as serial numbers, barcodes, and QR codes.

Minimal Thermal Impact: With the ability to adjust the pulse duration, MOPA lasers reduce the risk of heat-induced damage such as burning, melting, or warping on heat-sensitive materials, allowing for cleaner and more accurate marks.

High Peak Power: The high peak power of MOPA lasers makes them efficient for deep engraving, surface etching, and precise marking on challenging materials.

| Optical characteristics of Mopa Laser | |||

| N | Characteristics | Parameter value | Unit |

| 1 | Center wavelength | 1060-1080 | nm |

| 2 | Spectral width(FWHM) | < 20 | nm |

| 3 | Maximum pulse energy | 2 | mJ |

| 4 | Output Power | 100 | W |

| 5 | Power adjustment range | 0-100 | % |

| 6 | Frequency adjustment range | 1-3000 | kHz |

| 7 | On/off light response time | < 20 | μs |

| 8 | Pulse Width | 2-500 | ns |

| 9 | Output power stability | < 5 | % |

| 10 | Beam quality M² | < 1.8 | / |

| 11 | Polarization direction | Random | / |

| 12 | Resist high reaction | Yes | / |

| 13 | Indication (red) optical power | 0.3-2 | mW |

| 14 | Collimated Beam diameter (4σ) | 7(10mm optional) | mm |

| 15 | Delivery cable length | 3 (5m can be customized) | m |

| Electrical characteristics of Mopa laser | |||

| N | Characteristics | Parameter value | Unit |

| 16 | Supply voltage | 48 | V |

| 17 | Working current | < 10 | A |

| 18 | Power consumption | <480 | W |

| 19 | Recommended power supply | ≥600 | W |

| Environmental requirements of Mopa laser | |||

| N | Characteristics | Parameter value | Unit |

| 20 | Working temperature | 0-40 | ℃ |

| 21 | Storage temperature | -70 | ℃ |

| 22 | Cooling Method | Air cooling | / |

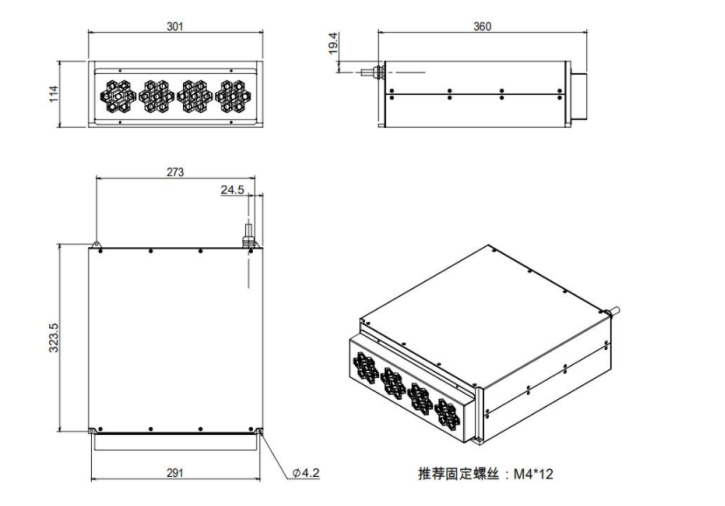

| Structural characteristics of Mopa laser | |||

| N | Characteristics | Parameter value | Unit |

| 23 | Laser dimension | 360*301*114 | mm³ |

| 24 | Isolator size | 283.5*50*50 | mm³ |

| 254*50*50 | |||

| 25 | Net weight | <15 | kg |