Time:2023-02-28

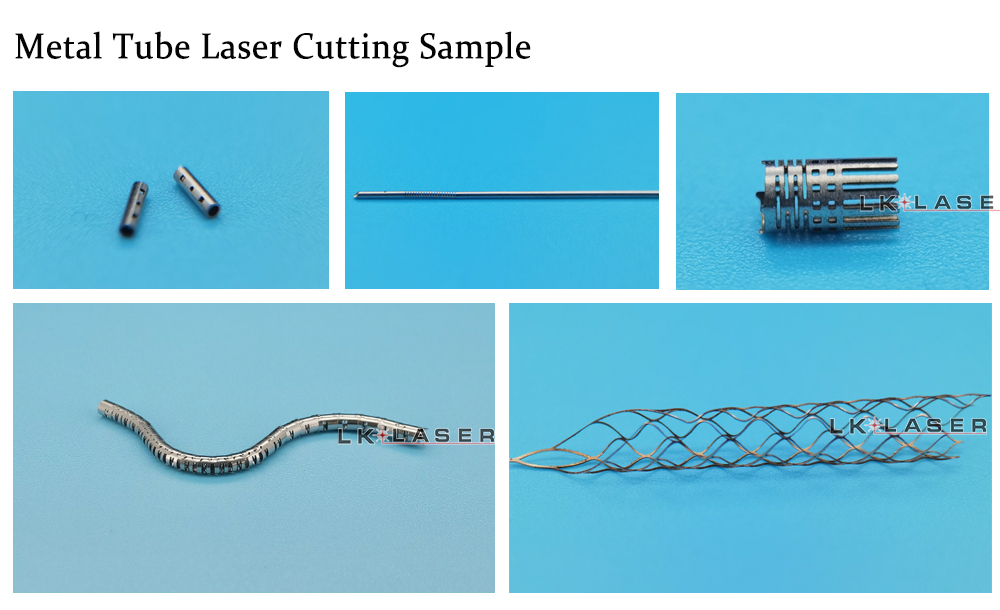

production of medical metal tube is highly demanding because it is often used in applications such as medical devices, surgical tools and implants stent where safety and accuracy are required.

accrding those requests LK Laser medical tube laser cutting machine is an excellent tool for the medical industry due to being a contactless high-speed cutting with high resolution. could cutting commonly medical materials include stainless steel (such as 316L), titanium alloy (such as Ti-6Al-4V), nickel-titanium alloy, etc.

those tube materail was maintain strength under high stress conditions and have a certain toughness to prevent breakage. so our laser cutting machine with high stable and accruacy tube kit support structure and also lk laser machine with non-contacting cutting process with mimimuizes heat-affected zones,preserving the integrity and proformace of thin wall pipe material , laser cutting medical tube could pass the mechanical properties testing: includes tensile, compression and bending tests to verify that the mechanical properties of the tube meet medical standards

and LK laser high precision tube laser cutting machine with fine fiber beam and excellent laser processing quality make clean cuts optimize kerf surface clean eadges with burrs which could pass the strict quality testing and non-destructive testing such as X-ray, ultrasonic testing, etc, laser cutting methods make medical tube without crackes, proes,ensure uniformity and the absence of harmful phases.

Lk laser stent laser cutting machine adopt high precision cutting and automatic programming system and professional cutting software for processing various types of pipes. It seamlessly connects with the layout size to achieve precise cutting processing of layout, common edge, basic process and special process of parts. By collecting Z-axis information in real time, the deviation value between the center of the pipe and the rotation center of the chuck is obtained. Real-time compensation is performed on the subsequent graphics to be cut to achieve high-precision processing. The workpiece mode uses a fixed tool zero point, which is suitable for punching the cut pipe. The floating mode uses the Y coordinate of the current cutting head as the tool zero point, which is suitable for arbitrary processing anytime and anywhere. The support function of the pipe support structure can be fully automatically raised or lowered according to the position of the chuck, and the support has an automatic alarm function to ensure the absolute safety between the chuck and the support. At the same time, the support can also be used to achieve the purpose of automatic unloading. In view of the problems of difficult cutting and poor cutting of pipe corners, the pipe corner process is specially introduced. By debugging and setting a set of reasonable corner air pressure, peak power, duty cycle, etc., the cutting of the pipe corner is faster and more perfect.

thsoe functions make leikang laser machine can perform laser drilling, grooving and cutting according to customers’ special design and processing requirements. could adapt medical tube with different outer diameter, inner diameter and wall thickness, materail range. The cutting deviation reaches the micron level, ensuring the reliability and functionality in medical applications.

Related Products

High Precision Medica Tube Laser Cutting Machine

Model Number -LK-JWM

Power options: 200W/ 500W/ 1000W/ 1500W/ 2000W

CNC system options: 3 axis/ 4 axis/ 5 axis

Could provide customization machine design & service

Advantages

·Support cutting complex design: machine adopt high-precision cutting and pipe support structure to ensure the consistency of relative processing position and support rib width, and can cut complex shapes

·Clean Cuts: non-contact cutting process of laser cutting optimize kerf surface clean edges without burrs,

·Versatility: Capable of cutting a wide range of metal materail such as stainless steel, platinum tube, Ni-ti tube........

·Minimal Thermal Damage: Laser cutting minimizes heat-affected zones, preserving the integrity and proformace of the thin wall pipe materials.

·High Speed and Efficiency: High cutting speeds and automation capabilities enhance production efficiency and reduce cutting times

Application range

Used in cut manufacturing of catheter stent, endoscopic Instruments, needle, hypotube, ultrasonic scalpel,

breast cannula, flexible pipe cutting, Implant pipe......with different wall thickness and diameter